ABOUT US

Our Company Established in the year 2005 and successfully marching into 18th Year. We at NSK as a part of Women Empowerment, employed more than 80% of Women employees and contribute to Social Welfare Activities.

About Us

Leader In Engineering

NSK Automotive supplies the parts to all major OEM applications such as Flywheel Assembly, Crank & Alternator pulley Assembly, Housing & Hub Adapters, Flange Output Shaft, Brake Pistons, Torque Pins, Grooved Pulleys, Specialty Fasteners, etc. We have installed highly sophisticated Measurement Systems like CMM, Contour Measurement system Profile Projector, surface finish tester, etc., and Manufacturing facilities like CNC – Turning, Machining, Broaching, Grinding, and supporting activities such as Heat treatment and Plating.

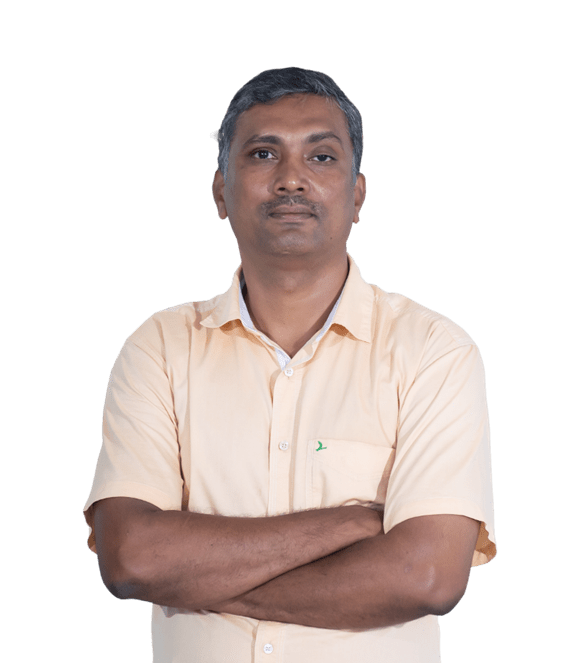

MR. Sivakumar

CEO & Founder

Entrepreneurial Leadership: As the founder and CEO of NSK Automotive, entrepreneurial journey reflects innovative thinking and strategic planning, driving the company’s growth and success.

Engineering Expertise: BE Mechanical Engineering with 23 years of experience, possess a strong background in Mechanical Engineering, specializing in Quality control, Quality Management Systems, New Product Developments, vendor incubation, customer relations, process optimization, and procurement strategies.

Industry Influence: NSK Automotive has made a significant impact in the manufacturing sector, influencing industry standards and technological advancements.

MR. Gopalakrishnan

Managing Director

Manufacturing Excellence: BE Automobile Engineering with 24 years of experience and excel in Design, Development, Manufacturing process, Quality, and industry trends. Hands-on experience ensures high-quality products and services.

Leadership: As a Managing Director, demonstrate effective leadership, fostering a collaborative and innovative work environment.

Business Growth and Innovation: Have successfully led the company in identifying growth opportunities, developing new strategies, and establishing partnerships, driving innovation in the manufacturing sector.

Core Values

We are truly driven by our values to make engineering solutions available to everyone. We not only intend to bring change but also to intend to make it self-sustainable

Our Mission

The employees and management of NSK Automotive are committed to providing only the highest quality products and services to our customers. NSK Automotive Is continuously developing and improving manufacturing methods to ensure the highest possible level of value, quality, and products.

Our Vision

NSK Automotive will set the standard for excellence in manufacturing and supply of Machined Components for Automotive Applications. We will provide unequaled value to our customers. We will continuously work to improve the lives of our people. We conduct ourselves with integrity and professionalism.

Our Values

NSK Automotive Is Committed to understanding and fulfilling our interested parties’ requirements and providing error-free Machined Components on – time to derive, delight by establishing a system with continual improvement and meeting the statutory & regulatory requirements at all times.

Journey so far

2005

NSK Automotive Launched at Unit 1 (2,00,000 components / year)

2006

Became supplier to ILJIN Automotive Ltd.

Overall production volume hit 5,00,000 /

2007

ISO 9001:2000 Certification

2009

2010

Production hit a record high – 15 Lakhs (1.5 Million) / year

2011

Started supplying Automotive Transmission

Sub-Parts and VAS Parts

2012

Started Supplying to Medical Equipment Parts

2015

Started Supplying to Passenger, Commercial, and off-road Vehicles

2018

ISO 9001:2015 by BSI

2020

Started supplying to CMBF Trading & Manufacturing India Pvt. Ltd and Mining Vehicle Brake Assembly sub-parts

2021

#1 Best Supplier Award from Gates Unitta India Company Pvt. Ltd. Production increased up to 2.4 Million / year.

2022

Opened Unit 2 for handling volume (Automotive – Heavy Vehicles’ Parts)

2023

Opened Unit 3 for handling volume (Specialty fasteners

2024

Construction of Unit 4 for handling additional volume (Medical and non-Automotive Parts). Currently we anticipate to produce up to 3 Million Parts / year

Journey so far

2005

NSK Automotive Launched at Unit 1 (2,00,000 components / year)

2006

Became supplier to ILJIN Automotive Ltd.

Overall production volume hit 5,00,000 /

2007

Started supplying to Non-Automotive Sectors

ISO 9001:2000 Certification

2009

2010

ISO 9001:2008 Certification.

Production hit a record high – 15 Lakhs (1.5 Million) / year

2011

Started supplying Automotive Transmission. Sub-Parts and VAS Parts

2012

ISO/TS 16949:2009

Started Supplying to Medical Equipment Parts

2015

Started Supplying to Passenger, Commercial, and off-road Vehicles

2018

Certified IATF 16949:2016 &

ISO 9001:2015 by BSI

2020

Started supplying to CMBF Trading & Manufacturing India Pvt. Ltd and Mining Vehicle Brake Assembly sub-parts.

2021

#1 Best Supplier Award from Gates Unitta India Company Pvt. Ltd. Production increased up to 2.4 Million / year.

2022

Opened Unit 2 for handling volume (Automotive – Heavy Vehicles’ Parts).

2023

Opened Unit 3 for handling volume (Specialty fasteners).

2024

Construction of Unit 4 for handling additional volume (Medical and non-Automotive Parts). Currently we anticipate to produce up to 3 Million Parts / year.

Women

Women Empowerment

NSK strives to enhance the communities we live in and empowers women employees to give back via corporate social responsibility. NSK Automotive plays a key part in our efforts on Diversity, Equity, and Inclusion.

At NSK as a part of women empowerment, we employed more than 80% of our workforce with female/women-centric employees and contribute to various social welfare activities

%

Women Employees

Sunrise Meetings

At NSK we follow a proven ongoing agile process – Sunrise Meeting. This is a daily stand-up safety meeting to ensure all the protocols are followed by the employees on the shop floor.

Through our ongoing safety, quality, and production meetings, coupled with our established monitoring systems, we have attained a flawless safety record with zero recordable incidents and zero lost time cases.

Training & Development

- We conduct continuous skill development in-person programs

- Training in high-precision parts manufacturing processes significantly benefits all stakeholders

- Yearly we conduct 12+ trainings

As a retention strategy, we adhere to the best practices such as:

- Employee Engagement

- Job Enrichment

- Empowerment (esp. Women Empowerment)

- Training & Education

- Motivation

- Rewards & Recognition

Attrition ratio of < 2% between 2018 ~ 2023

AUTOMOTIVE

We cater the following parts to the automotive industries such as Pulley Hub, Idler Pulleys, Sleeves, Spacers, Adapters, etc.

Non- AUTOMOTIVE

We cater the following parts to the non-automotive industries such as Tensioner Pulleys, Adapter Housings, Housing Adapters, etc.

General Engineering

We cater the following parts to the general engineering industries such as stop plate for radial plate, Lightning Conductor Plate, Tube Greasing, etc

Medical Applications

We cater the following parts to the medical applications such as DFS pedal insert, DHP stem – db3, Cm enclosure insert (front) – ICLS, Oto handle ring – OPD, OTP heat sink, etc.

IATF 16949:2019 & ISO 9001:2015 CERTIFIED

We are accredited as the best in the industry and achieved 100 PPM certification from Hyundai Motor India Limited in the year 2012. This commitment was also reflected to certify NSK Automotive as ISO 9001:2015 as we comply with the requirements of ISO 9001:2015 from BSI in the year 2018. As we strictly adhere to the quality management system for the machined components we are also certified by IATF 16949:2019.